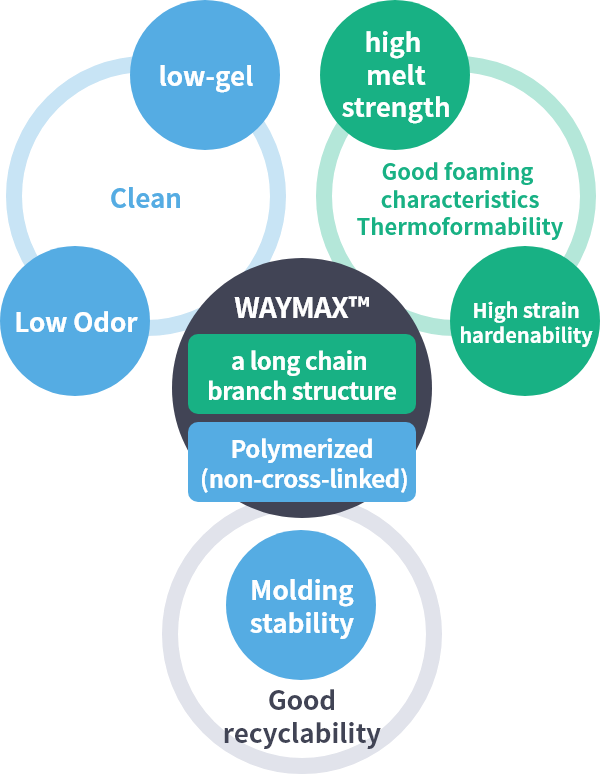

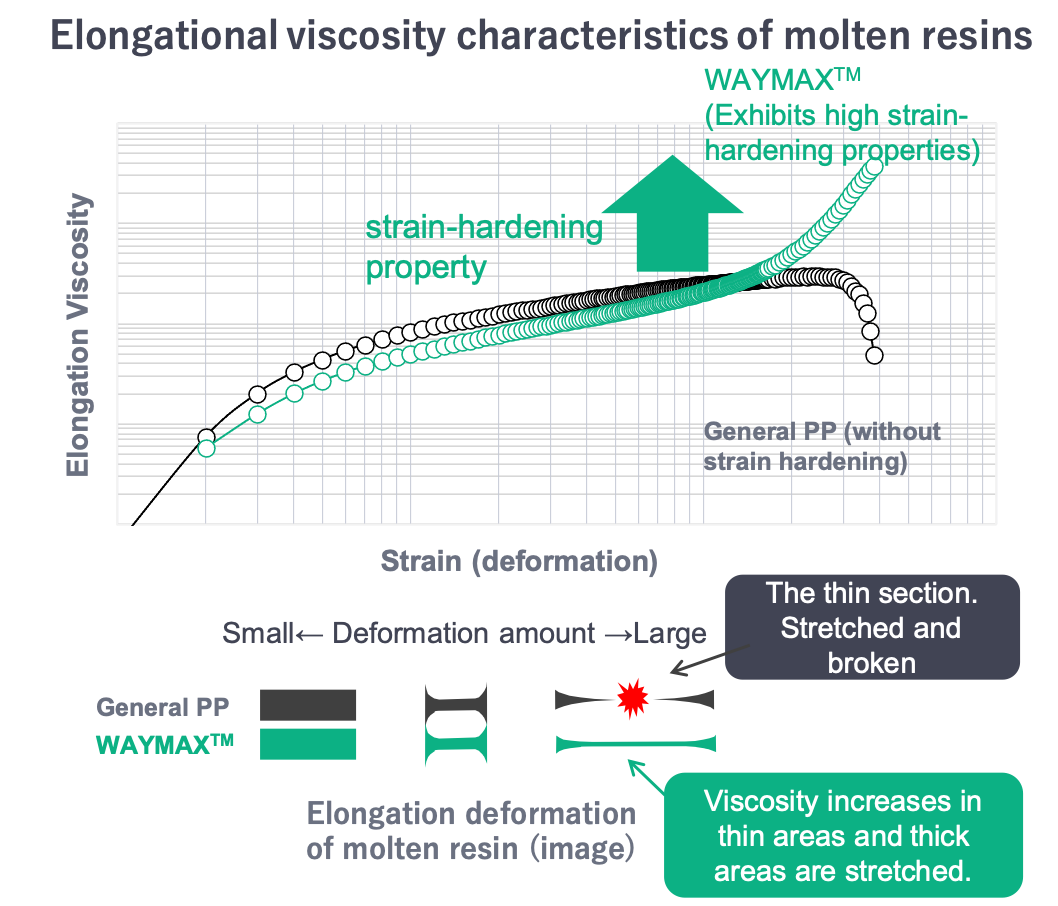

WAYMAX™ is a long-chain branched (LCB) high melt-strength polypropylene (HMS-PP) using an original metallocene catalyst technology developed by Japan Polypropylene Corporation.

Core Technology Details

Conventional HMS-PP is mainly produced by introducing a long-chain branched structure by denaturation using radiation or peroxide, which causes problems such as a significant decrease in melt strength after extrusion, inclusion of components (gel) that deteriorate the appearance of films and other products, and poor recyclability. However, we have succeeded in solving these problems by introducing a long chain branched structure using our original metallocene catalyst technology and polymerization technology.

WAYMAX™ has excellent melt properties derived from the structure described above and can also exhibit excellent heat stability at the same time due to the absence of a denaturation process.

These features enable stable and well-balanced expression of properties such as melt strength and recyclability even under mass extrusion conditions and are expected to greatly improve productivity in molding methods such as foam molding and thermoforming of large or deep-drawn parts, as well as stability of product properties. In the field of PP-based films, it is also expected to be used as a modifier due to its extremely low gel and greatly improved film-forming properties.

WAYMAX™ Performance

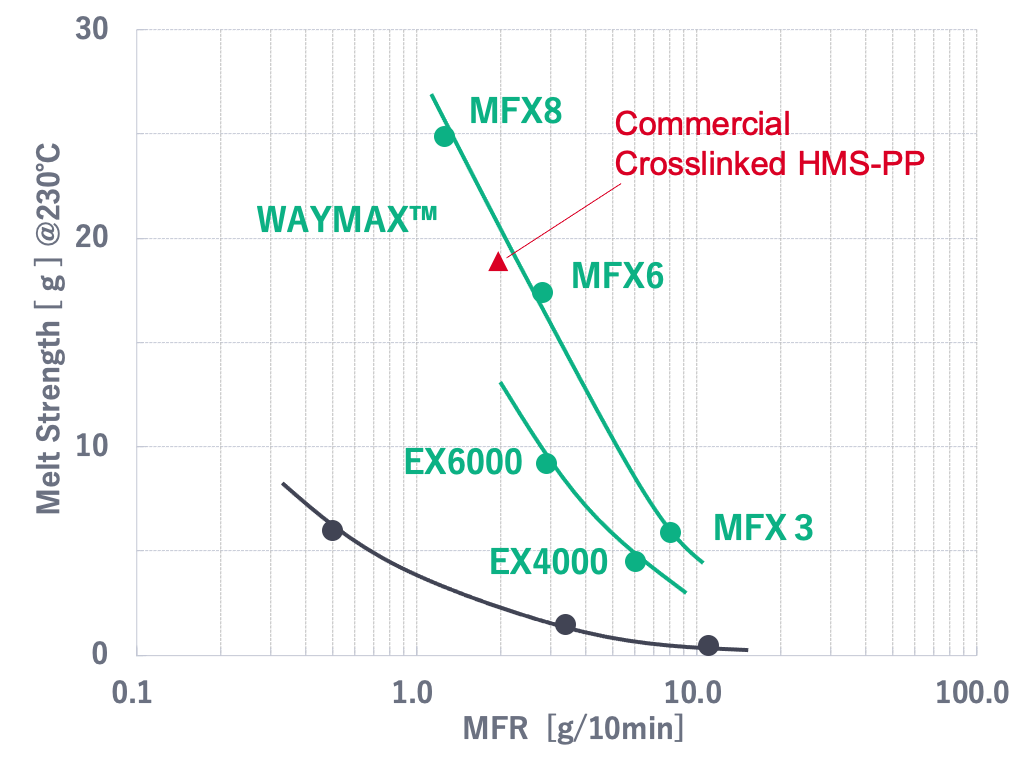

Excellent melting characteristics

Excellent balance between melt strength and flowability.

Excellent balance between melt strength and flowability.

Molding stability

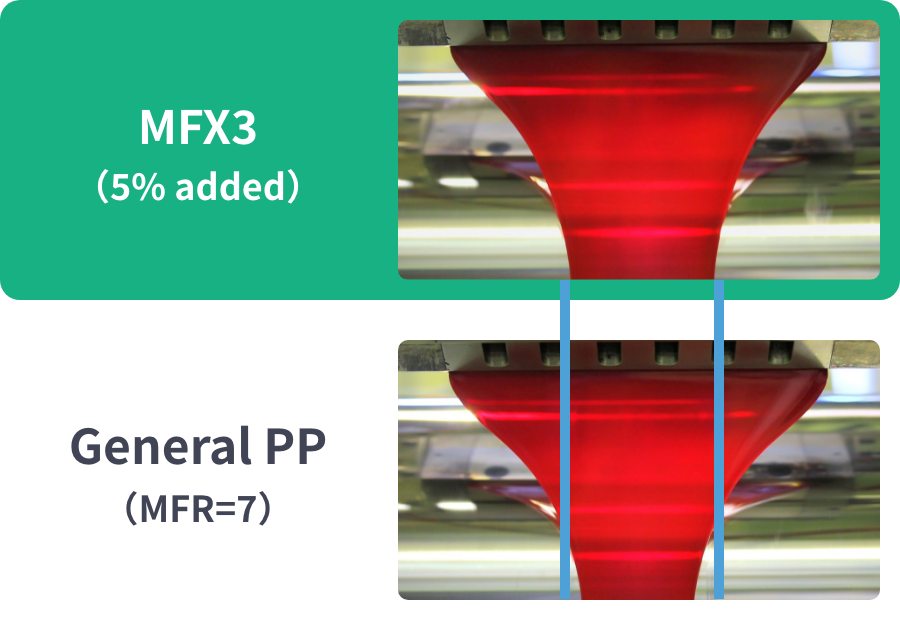

Suppression of neck-in and draw resonance can improve productivity

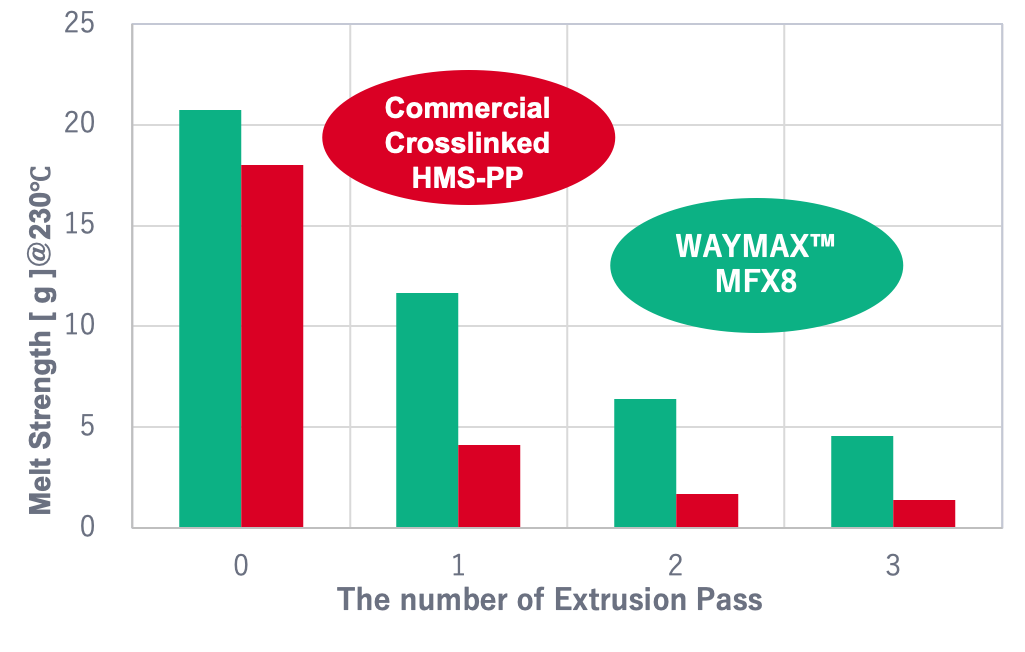

Compared to cross-linked HMS-PP, there is less increase in MFR and decrease in melt strength during repeated extrusion, resulting in excellent molding stability and recyclability.

It is also cleaner than cross-linked HMS-PP, with less volatile gas emissions.

Bubble stabilization in air-cooled inflation film molding

General PP(MFR=7)

WAYMAX™ MFX3(5% added)

Application examples

This is examples of product applications that takes advantage of the characteristics of WAYMAX™.

Foam Container Applications

Injection foaming applications

Thermoforming applications

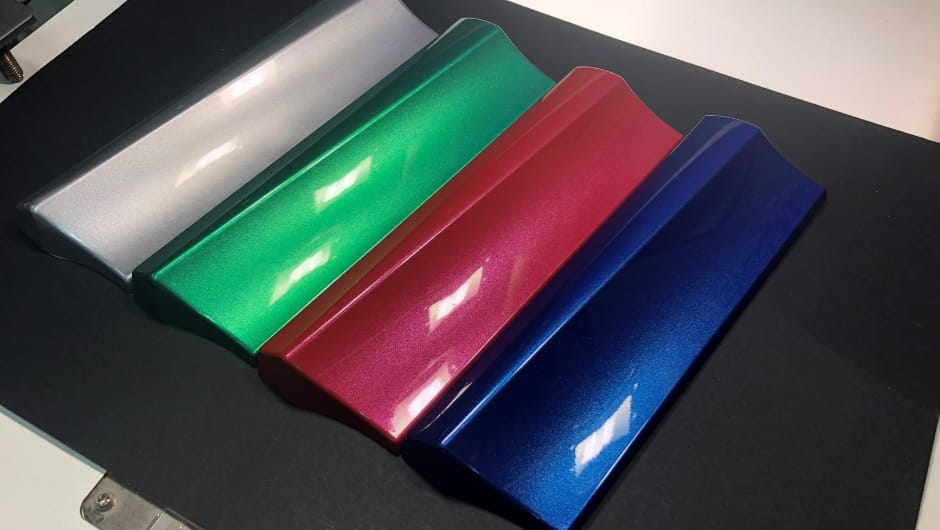

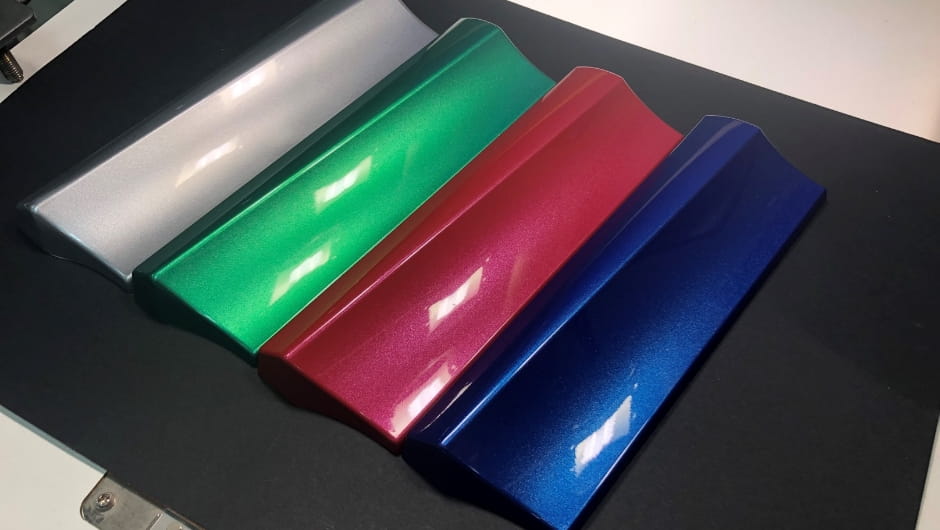

Decorative Film Applications

Grade list/Download

Physical properties of WAYMAX™

- This is a typical data, not to be construed as specification.

- Application suitability should be confirmed with the final product by referring to the physical property values.