"WINTEC™" is a completely new PP with a homogeneous molecular structure and a variety of performance features that conventional catalysts cannot achieve.

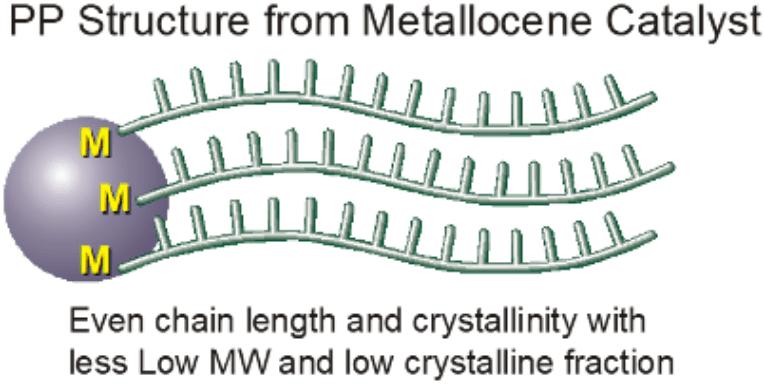

The original metallocene catalyst technology developed by Japan Polypropylene Corporation makes it possible to create the PP polymer molecular structure as intended.

Metallocene catalyst

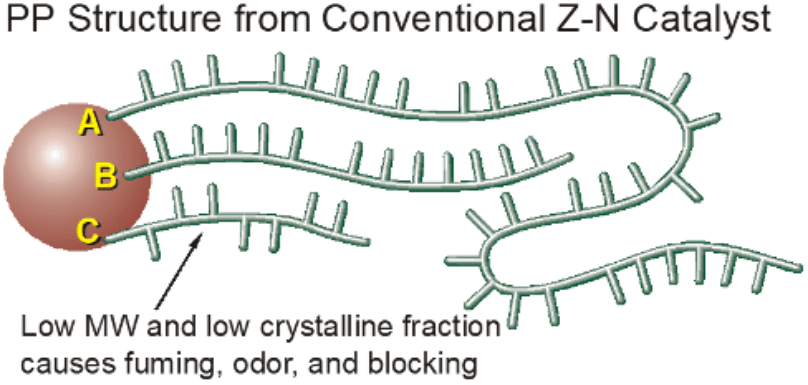

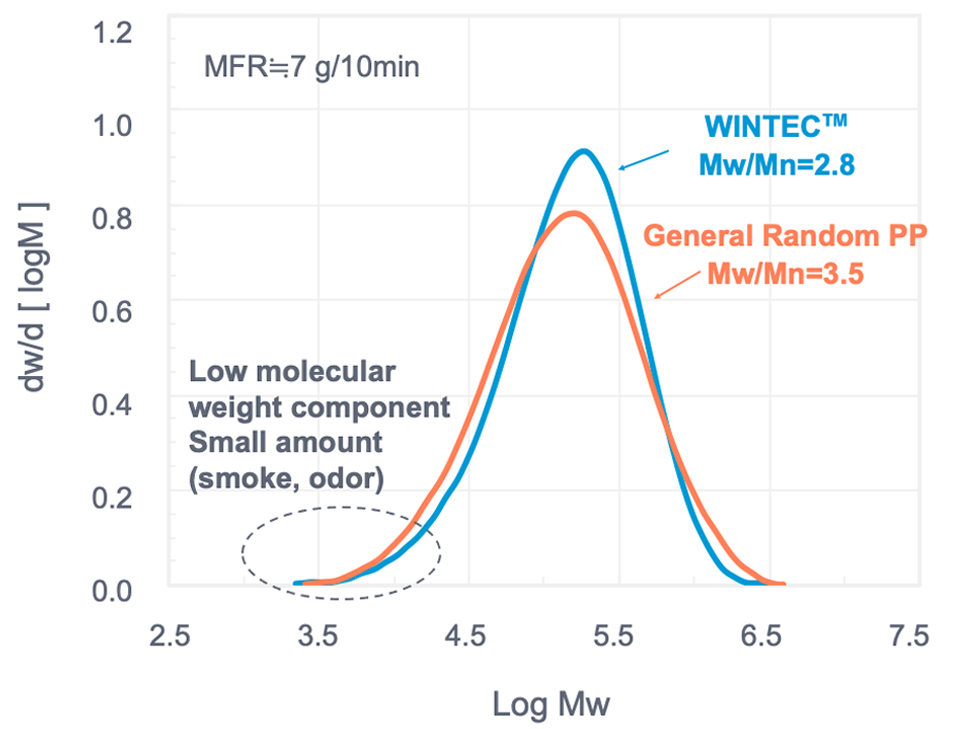

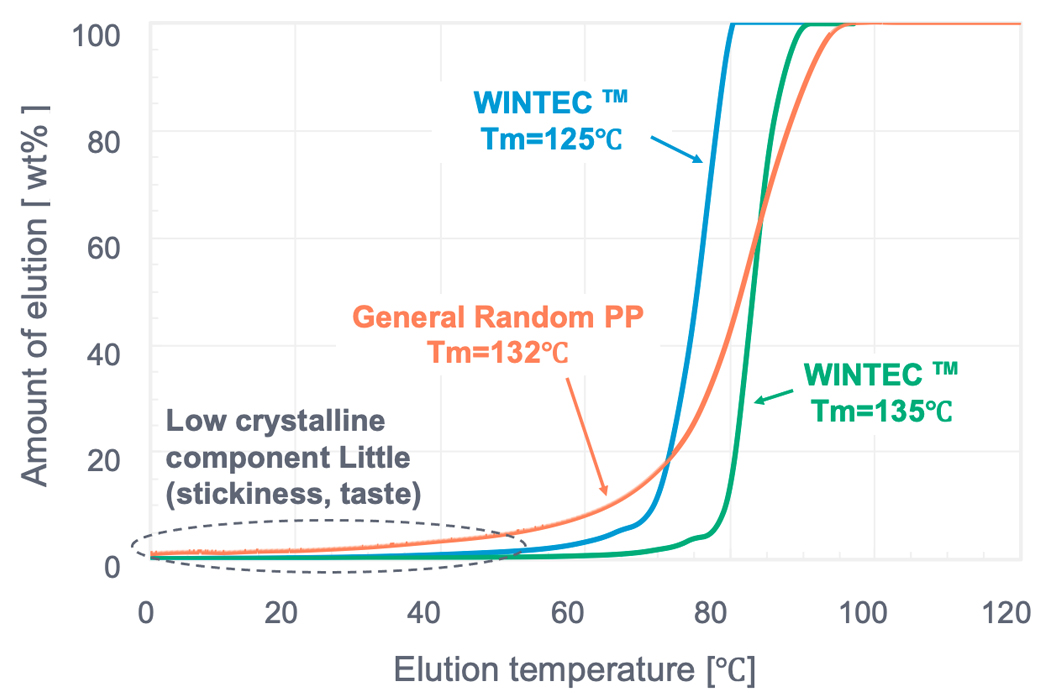

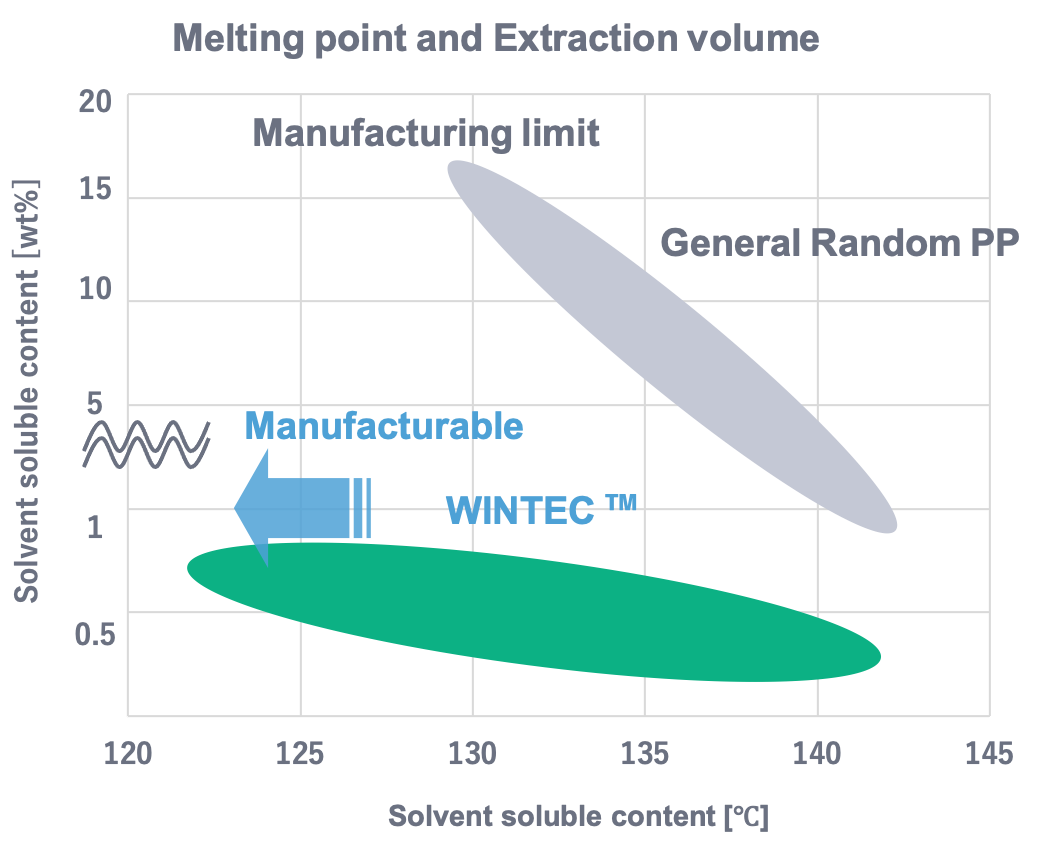

Metallocene PP WINTEC™ is characterized by its slim molecular structure, which significantly reduces unnecessary low molecular weight and low crystallinity components by narrowing the crystallinity (regularity) and molecular weight distribution.

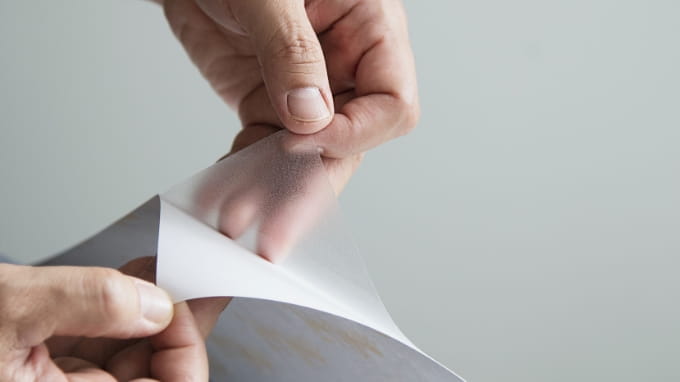

This results in a clean material with little smoke generation, roll staining, product stickiness, or odor during molding. It also has excellent solvent extraction resistance, making it suitable for food packaging and medical applications.

In addition, for random PP (ethylene-propylene random copolymer), we have succeeded in developing PP with an ultra-low melting point, which could not be achieved with conventional catalysts. This PP offers unprecedented and outstanding performance in applications such as heat-sealing films.

WINTEC™ Features

WINTEC™ also has the following other features that are expected to provide an excellent balance of properties in many application areas.

| Characteristics of Molecular Structure | Expected Performance | Uses, etc. |

|---|---|---|

|

|

|

|

|

|

|

|

|

The new performance of PP realized by WINTEC™ has the potential for a variety of application developments.

Through WINTEC™, Japan Polypropylene Corporation proposes new ways to use PP.

Application examples

This is examples of product applications that takes advantage of the characteristics of WINTEC™.

Highly transparent packaging container applications

Clean Packaging Container Applications

Hinge Cap Applications

Low temperature heat sealing Applications

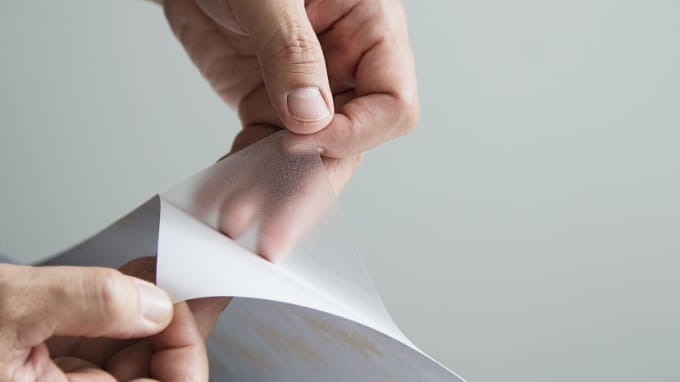

Surface Protective Film Applications

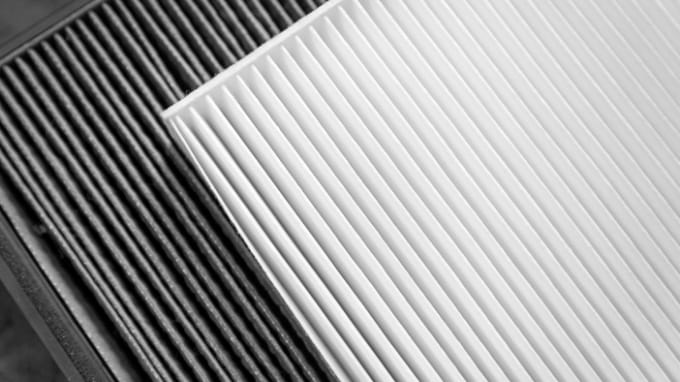

Nonwoven Fabric Applications

Autoclave Sterilizable Medical Components

Grade list/Download

Physical properties of WINTEC™

- This is a typical data, not to be construed as specification.

- ・Application suitability should be confirmed with the final product by referring to the physical property values.